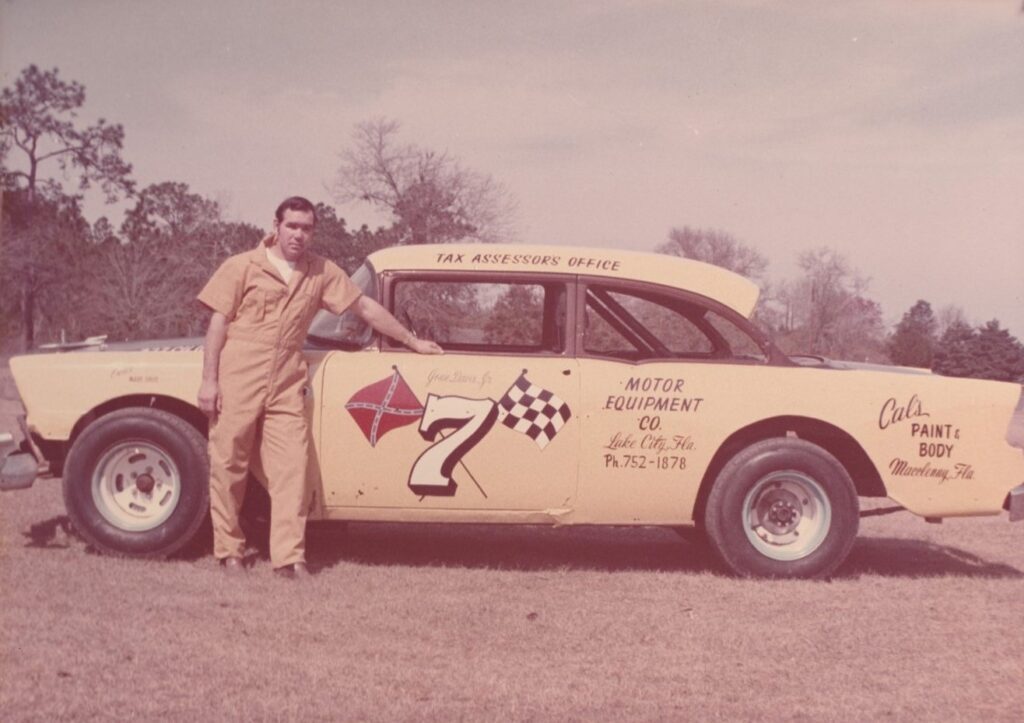

My grandfather started the fire as a heavy equipment operator in Volusia County Florida. His job included grading the famed Daytona Road course on A1A. From 1948-1959 his baby was the “Beach course”. In 1959 Big Bill started building the Daytona speedway, my grandfather was approached to work as a contract laborer paid in shares/ IOU’s. My grandfather told Bill I got a family to feed, can’t do it. My Dad from 12 years old to age 20 stood on the old motor grader in the north turn soaking up the “want to”. Most kids in the 1950’s were feral in nature, my dad lived in Volusia County, FL and that meant all of Volusia County, if you could get there on a bike or walking it was fair game. My dad loved speed weeks, racers came every winter to Daytona, my dad would hang on the fence a Fish Carburetor, watch them dyno cars for days, watch the teams time trial on the beach, went to the golf course and talk to racers as they played, all fueled a desire to race, that “want to” turned into a 60 adventure for the both of us. In the late 1966 we moved to Lake City, FL, dad was chasing a different option but ended up working construction in Jax, FL. He told my mom to find a place to settle down between Lake City and Jax, Macclenny, FL was the spot. It wasn’t long my dad was drawn back to the racetrack by fellow workers. We went to Jax Speedway Park every Saturday Night until 1970. My cousin and dad had started a car in 1968, a 1956 Chevy, no money, not a lot of know-how, limited resources, a slab in a swamp, a subscription to stock car magazine, a bunch of HP how to books, and a cutting torch. This was a turning point in this adventure. As an 8-year-old I was exposed to a trait that my dad had that when he wanted something that included something he didn’t know he laser focused on the topic until he was satisfied he mastered it. This is the point that every ounce of knowledge in the Makers IP started. The process to gain the knowledge was random at best, I can remember recon missions where we visited folk’s dad had befriended, Everette Pop Moran was always a great source of information, I went to school with his grandsons, lifelong friends, Wally Ferry owned United Auto Parts had a history with the racers of Jax Speedway Park, Johnny Vogel a dude my dad met on a construction site spent many a night in a carport checking that circus out. My dad befriended a car builder with a history in the Carolinas, Sonny Hawkins we spent hours in class with Sonny.

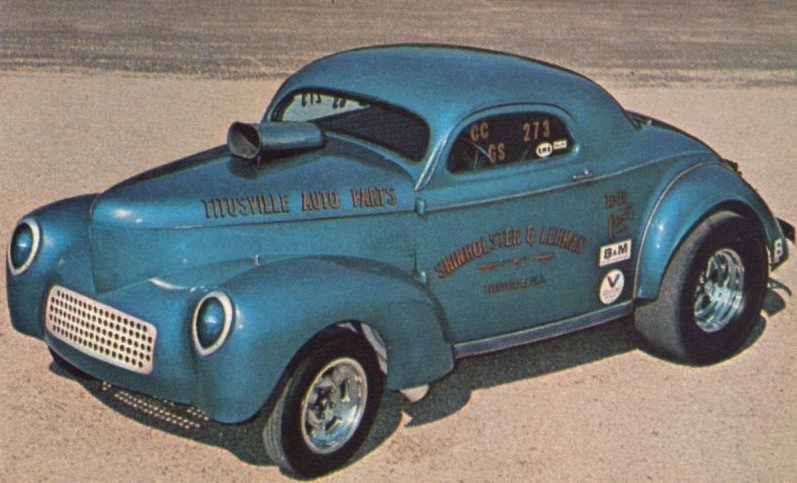

I think one of the most impressive adventures was visiting Curtis Lehman that owned the famed Shin holster & Lehman gasser, on the northside of Titusville, FL where he worked in his carport. Every visit we studied the car. Curtis was involved with the Corvette program early on, a Zora Arkus Duntov disciple, he always pushed volumetric efficiency, his go to was 1hp x 1cu x 1cfm x 10lb car wt. He had a 300 hp, 300 cu in, 300cfm, 3000 lb. gasser that set world records in 1971. He ran several carb combos cc bb gas stuff. We left with two givens that day, lightweight is king, volume and power are relative. My dad was on a mission, his thought process was like his project management style all aspects needed to converge at a final destination. Dad never allowed a need to change in direction become an issue. A valuable lesson I teach every day to my teams, I hate to waste time, but along the development path is the time to perfect, not realizing that your results are lacking.

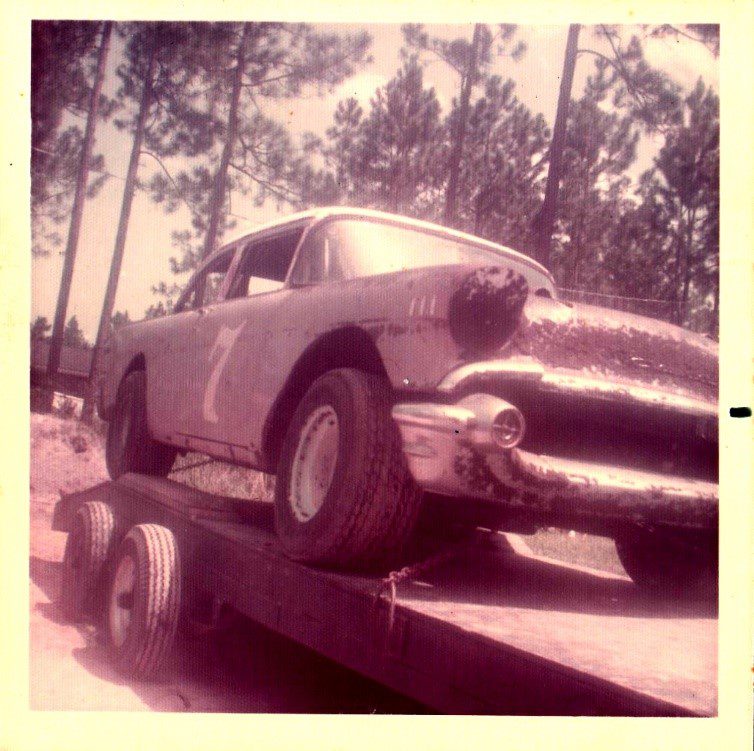

There were several factors that lead to the decision ditch the first 1956 project, Wally Ferry wanted it for R.J. Dickie Ferry to keep him off the street racing scene and get him into organized racing, my cousin John Moore and Uncle Larry Miller both lost interest, but the biggest factor was money. The slab in the swamp wasn’t working, a new brother ‘Matthew Scott” was born in 1969, the idea to walk away from construction and into body repair fueled the fire for a place to work. The Jones Shop was the place. As 1970 season rolled around our interest changed from Jax Speedway Park to Lake City Speedway, although secondary in nature, the thirst for race car information was still a priority for me, as I have said before racing was my passion, funding it was my mission. Even at 10 years old the body shop gave me an opportunity to make/save money, there were certain pots of money that dad allowed me to dedicate to the Cal Tech College Fund (racecar), the used bumper pile for the re-chromers, crashed batteries, aluminum trim/ scrap, and scrap metal. Trading was king, I was proficient at painting by 12 years old. This allowed me to save up a few thousand dollars. We got wind of a 56 two door sedan ready to put a cage in and by June of 1971 the second car was under construction. I gave $100 for the car, bought a roll cage from an abandoned race car for $50, traded a paint job for a truck rear end, and about 40 ft of schedule forty tubing. In my racing adventures with my dad, he tested my “want to” twice, after driving to north Jax to pick up the hubs, wheels and tires he called and asked are you sure you want to spend your savings on these parts, there is no turning back, I told him “it was obvious he wasn’t buying the parts and racing season was coming”. In those days we took the 61 Chevrolet lowers put the left on the right, right on the left, to correct a design flaw in the tri 5 cars, the ball joints were upside down, the opposite direction of the load, GM corrected this in the next generation of mid-sized Chevys. This allowed us to use a Lincoln spindle special sourced Timken bearings and 1965 Buick 45 Finned Aluminum Drums, I paid $200 dollars for all the junk yard parts, disassembled, sandblasted, magnafluxed, painted, reassembled. All new brake parts, Timken bearings, Moog ball joints and steering parts, were traded for painting Dickie Ferry’s race car. The rear end was a 1948 Studebaker 1-ton split housing with an Honest Charley 6.17 rear gear, and a set of Franklin 10 ¼ bolt pattern aluminum hubs with 45 fin Buick Aluminum Hubs. The rear housing was disassembled spring perches removed, replaced, tubes straightened, painted, reassembled, then installed. In 1971 Steve Smith started a racing information project and printed several books, we jumped at the opportunity, the books included but were not limited to basic alignment theories. From the start my forte has been chassis alignment. Racers treated it as magic, smoke and mirrors, I was obsessed with and chased the alignment rabbit using design parameters in OEM manuals. By the time I was 12 years old, I drew full scale single dimension drawings on masking paper. I created models using welding wire, I studied the geometry models forward from 1955-1965, studied OEM dealer notes, contacted the Hunter Alignment Training Center to get OEM alignment charts for design changes pertaining to each year.

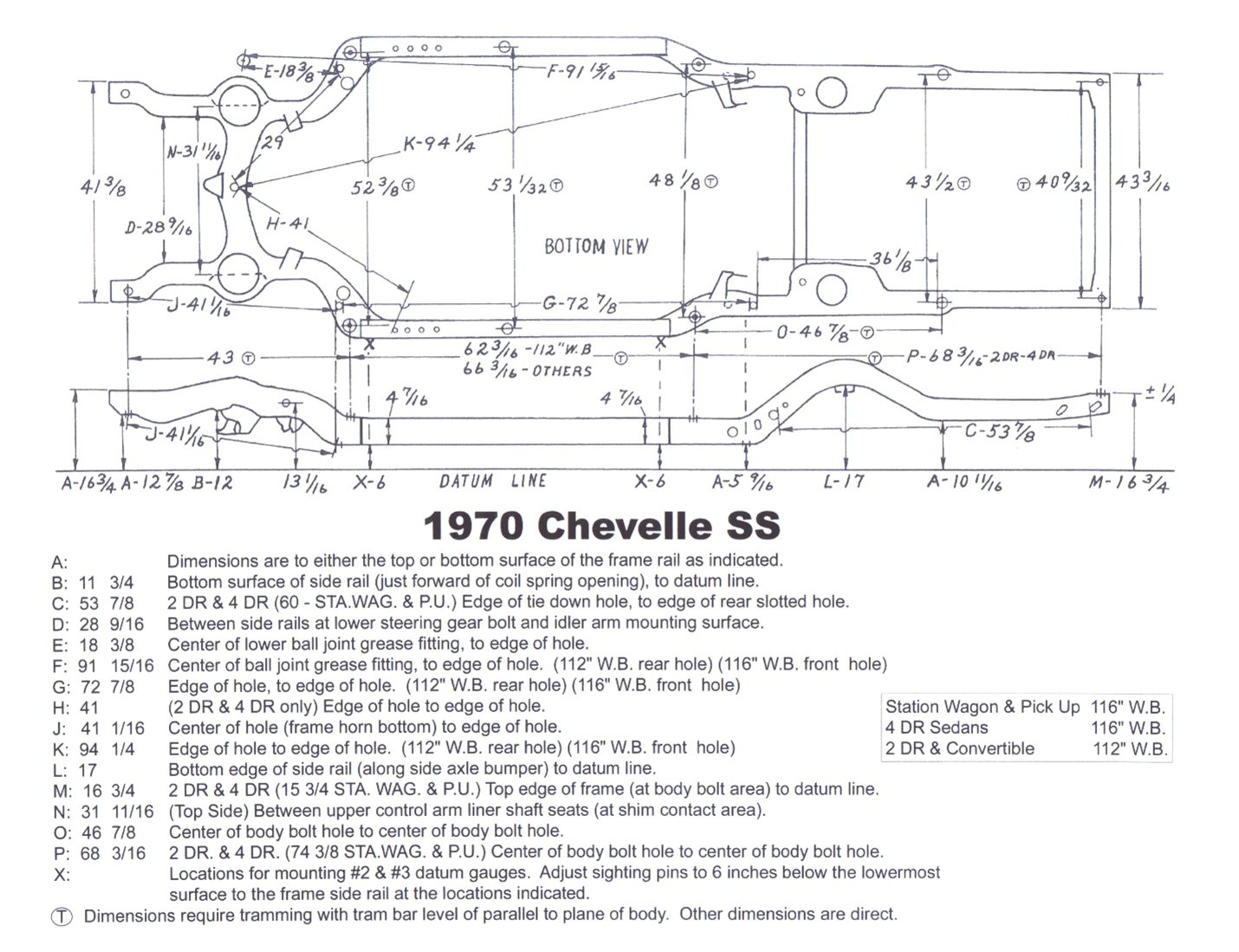

Cal’s Body Shop was known for heavy collision repair, we were experts in duplicating OEM manufacturing procedures, we used AO Smith alignment gauges and frame books. This knowledge and associated skills carried over into our racing. As GM engineering matured, I began to see trends, the trends seemed to follow motorsports, later in my career I got to meet many of the players and see the sequence of events on paper in the GM Tech Center. Alignment seemed to be the key, the truth is simple tire contact, grip is king, as my understanding matured, I was able to optimize the alignment, accept certain concepts, but more than anything, recognize and correlate the results of alignment changes. I came over to my gramps house one day he asked what I was drawing, I explained, he said GM spent millions and you’re going to make it better, I told him I was just trying to figure out if they are better! Early on insurance companies paid Cal’s to do structural repairs, 90% of the time this included front end alignment, a number of our techs were trained to align front ends, but for the purpose of making folks happy we used dealer service centers to align front ends. The local Ford store installed a new Hunter alignment system, they hired an ole racer trained in on the new system to align front ends. After a major repair my dad test drove an LTD, the car would turn a 100 ft radius one way a 150ft radius the other. After measuring the tie rods, I discovered the steering was off centered. All the alignment perimeters were correct but steering off centered. The same tech later aligned one of the local racer’s cars, the car ran strong. So, the monkey see crowd rushed to get some of his magic. A local racer came by the shop and told dad his car would not turn left at all. My dad and I both looked at the Caster/Camber/ Toe on both the racers racecars nothing stuck out, just for grins I measured the tie rods to determine steering center. After measuring the 1st car it turned 20* left 17* right, the other 15* left 20* right on the turn tables, we later discovered the alignment tech was never taught the 1st step in front end alignment to center the steering, he always just pulled the steering wheel after alignment and phased the wheel back straight. The concept of bump steer never entered the picture at that time.

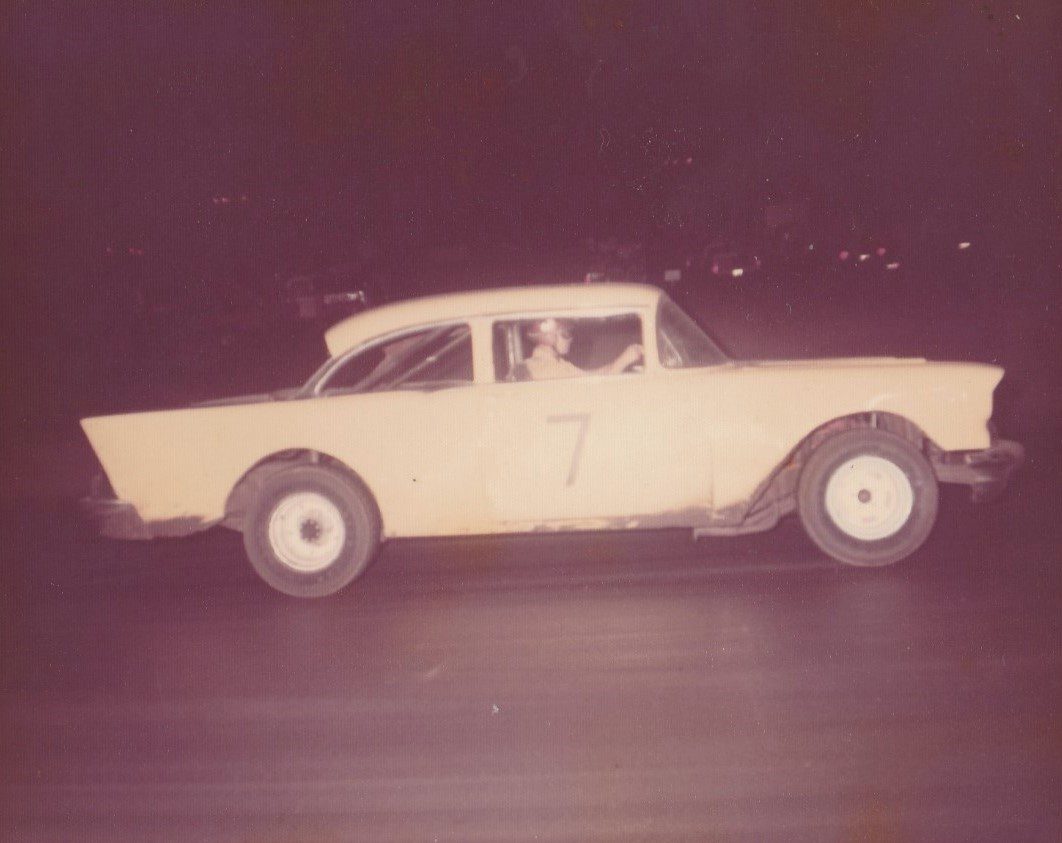

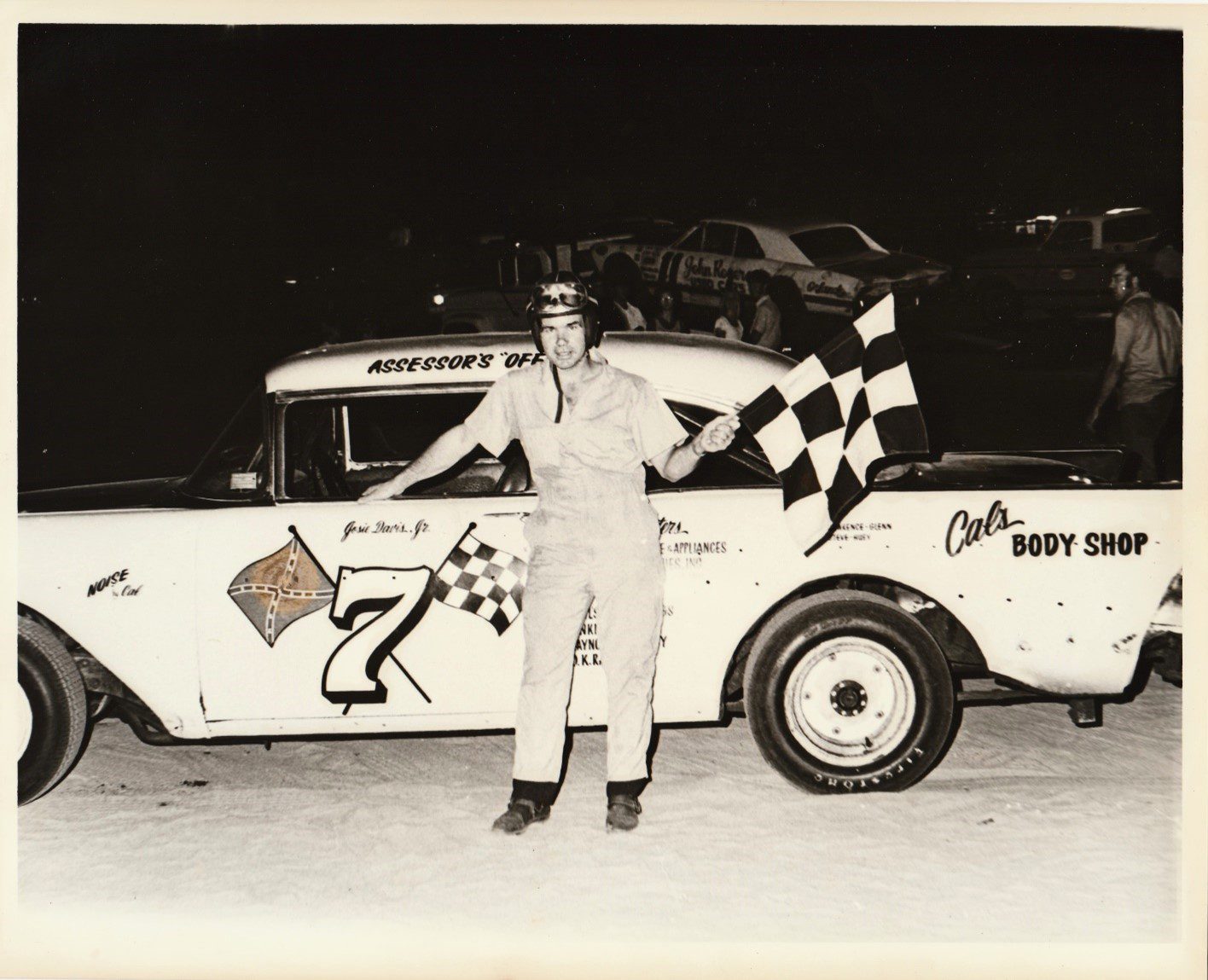

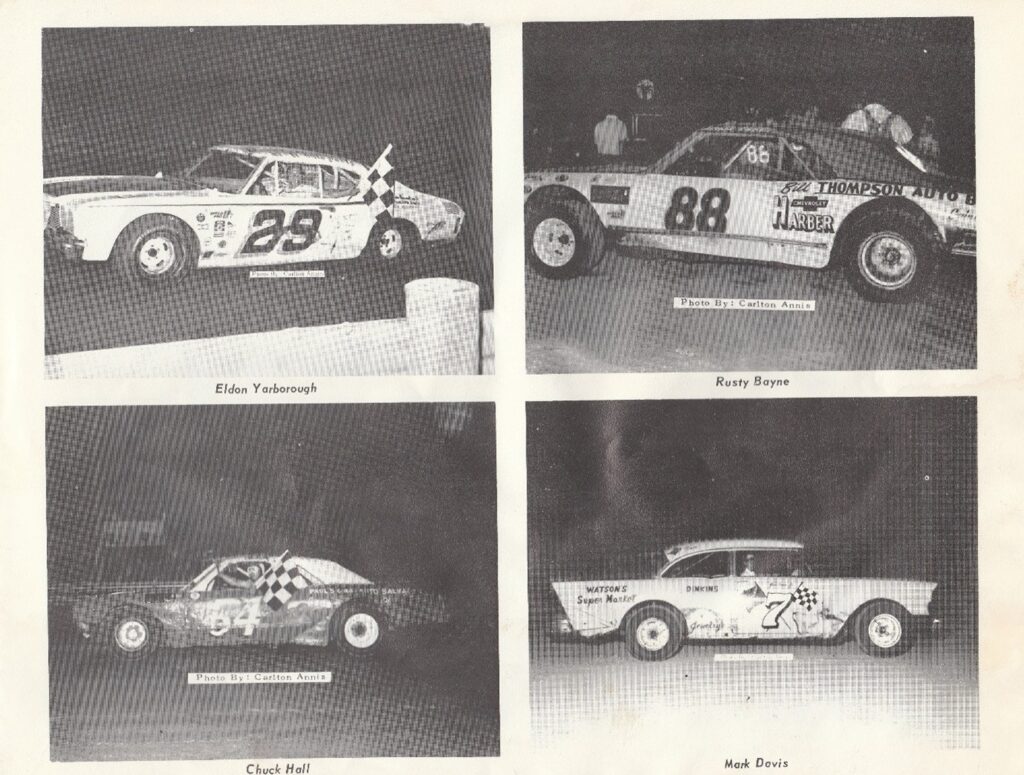

The 56 Chevy was our starting point, a lot of misunderstandings, miscalculations, but there were positives. Dad never lost sight of his friend Curtis Lehman’ 1hp x 1cu x 1cfm x 10lb car efficiency model. Circle track racing lends itself to overdoing things, track operators usually know a lot about getting into folks’ pockets, volumetric efficiency only applies to sellouts, we shot for, and the rules allowed unlimited hp x 440 cu in x 750 cfm with 9 lbs. per cubic inch. The rules changed to know weight limit, so our rabbit was 350 ci, 400hp, 3400 lb. car. We practiced the car a lot in 1972, dad tested the car most of the time, he had issues with orientation 10 or 12 laps at speed he would lose his location on track, being a pilot, it was directly relative to the horizon. Dad befriended a local politician, Josie Davis, no kin but friends for life, dad put Josie in the car, we chose to start the 1973 season. Early into 1973 as we were learning to race, Jax Speedway Park was shut down. Our home track Lake City Speedway was bombarded with cars, easily qualified 100 plus cars in two classes every Saturday night. In June a couple of Jax racers battling crashed totaling the 56.

I always felt that dad would have quit that day, but he despised Terry Mock for overdriving and destroying the car more. After the race, out of the blue a local dude that disliked Terry Mock as much as my dad, gave me a 1957 2dr sedan to build a replacement car. Car building stock bodied cars was a chore, depending on the car and the structural integrity you felt you needed from the stock body determined how light you wanted to go, the art of stripping a car was tedious. As major collusion experts every member of our team was experts in dismantling OEM cars, this is a big plus when building stock body cars. We wrecked the last week in June, Saturday 24th, on Sunday 25th, Huey Mercer a Navy weapons mechanic, and a butcher for Winn Dixie jumped in stripped the suspension. He told me something that day that shaped my approach getting big projects completed, he said “I can’t strip panels or weld, but I am a trained to disassemble & assemble anything, you need to utilize each team member according to their ability.” This stuck, I realized that as a team leader you should always compliment your talent with the freedom to use their ability to strengthen the program, that way they have an investment at that point. He got everything good off the 56, dragged the carcass out by the pine tree in the yard. We all had a vacation week July 1st– 8th coming up, picked up the 57 sedan and started to strip the OEM parts off the car on Monday the 26th. There was a dude Bud Helsabeck in Daytona that built roll cages, I contacted him he said roll the car bring the rolling white shell, and for $450 he would put in a 1.750 DOM tube roll cage next weekend, July1st- 3rd if we got the car to him. We picked up the car on the 5th from him. I remember my dad was adamant that this car be lighter than the 56, his vision was removing as much stock body as we could, our expertise let us strip the doors, fenders, deck, hood, and body down to the exterior skin. The secondary goal was to lower the mass, I used my random suspension studies to correct the geometry issues inherent with the tri 5 cars, by lowering the chassis. Inherently the A arm angles were challenged, I chased down stock spindles that complimented the issues and ended up with a Ford spindle. The 57 rolled on to the track July 22nd, qualified in the top ten, finished top ten.

The car was lightyears better, 500 lbs. lighter, suspension assembly was as precise as the car would allow, we retrofitted chevy police car heavy duty anti roll bars, better wheels, new tires. We raced out the season parked the car and decided to rest. As the 1974 season approached, we drug the 57 in the shop and charged the battery, freshened her up, and headed to the track. The engine we started with was a stock 1970 LT1, 350ci 400hp 11:1 compression, hydraulic lifters, long block crate replacement for the Corvette, the engine was better than the car, team, and driver. In 1973 dad started to build a long block to replace the tired LT1, we were able to get a burnt Corvette LT1 4 speed car, bored the block to .060 over with aftermarket 5.7 rods, de-stroked crank .080 back to 352 cu in. polished and ported LT1 heads to best of our ability/ knowledge, cut .100/ 13 to 1 compression ratio. 6 races into the 1973 season the stock LT1 laid down, 26 race weekends and a million practice laps the old girl wiped a rod bearing and started knocking. We brought the 57 in and changed the engine out, right back at it, the new kicker was strong but way different. Josie wasn’t a racer, he drove a racing car, not bad, but not as good as the car. Josie had a baby on the way, so practice soon on the early Saturday’s became my deal, I usually ran a couple 30-minute sessions every week, crazy everybody knew I was only15 but what the hay.

Nothing burns a crew out faster than knowing the car is faster than the driver. Mom lobbied to replace Josie with Jimmie Rance Andrews, I understood Dad’s unwritten contract with Josie, but he knew our team needed someone else and he discounted my ability. As the season wound down the future was obvious the Chevelles, Nova’s / Chevy II’s were lighter faster, Camaros were coming, the old sedans were going away. Eddie Studstill from Chiefland, FL wanted the 57 bad and dad just got the news from mom we spent $10000 in 1974 racing. She was adamant that things had to change to move on. Dad saw an easy opportunity to cancel the unwritten contract with Josie without ending his valued friendship. He told Eddie that he would sell every part we owned for $10000, spares, replacements, spare cars, 57 sedans and Chevelles everything. Eddie showed up with a semi and a briefcase, that was the end of chapter one. Note: Eddie’s team won over 20 races in 1975/76 with the 57 at the Dixie Speedway in Cross City.