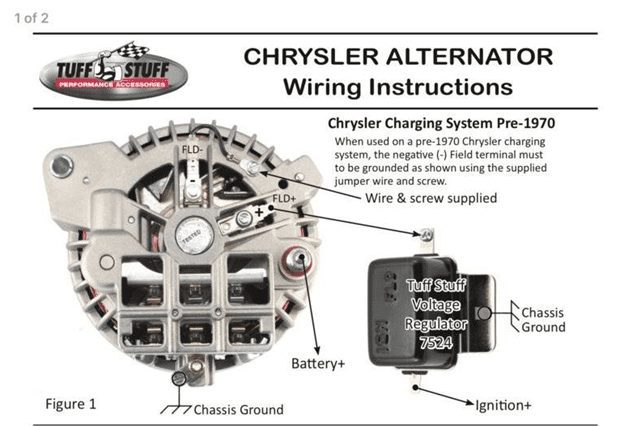

There are 2 things that I know hate being shocked one is me the other is pigs. There are multiples of relative lessons in the mechanics of life that carry over, one is the mystery of the negative ground. Shortly after my brother was born, we found out he had asthma, so severe that he was in the hospital 18 times in his first 18 months on earth. My dad chased back issues from a car wreck in his early teens and visited a chiropractor on a regular basis. The Dr. told my dad that he could relieve the asthma when Scott was having an attack. There was no doubt in the statement by any in our family, we saw the miracle on many occasions. My brother’s asthma challenged my dad from day one, my dad was in the carpenter’s union at the time of Scotts birth and although the income stream was challenged the conventional doctors’ bills were paid. The chiropractor bills not the same, knowing the results, dad did everything he could to complement their relationship without going bankrupt. The Doc had a new dodge van, it had been back and forth to the dealership 100 times constantly killing the battery. One day the Doc sicked my dad on the project, we had done a ton of work on the Doc’s rides to offset the bills, this was a way to buy some time. As many of our adventures Dad jumped in headfirst, the Dodge crowd had changed everything but the paint job on the van, even once opting to Lemon Law the beast. It was crazy everything worked from the battery until the battery was dead, alternator showed charging limited voltage, but take off the positive cable and everything shut down. The OEM trouble shooting guide addressed ground issues and Chrysler had a recall on engine grounds that included a starter ground cable that explained no issue starting with a full battery. We chased the ground system that included two new recalled cables. The system had a ground block with 3 wires, starter, block, and alternator. Chasing wires on a van can be troublesome, and the dealership had changed every component on the charging system, as I was chasing the OEM wire harness I noticed a pair of lugs, one was designated field, one designated ground, both wires were bolted to grd lug and had a positive wire that was connected to the regulator. Dad found the OEM picture of the 1970 alternator; the van was titled as a 1970 but had the manufacturing date 11/69 and every alternator installed on this particular van failed to connect the field ground therefore not activating the charging circuit. We contacted the dealership and the Mopar standard procedure network.

We later chased a ground issue on a restoration project built years ago, similar in nature, we totally disassembled the car refinished and reassembled the car. The majority of the 65 Mustang was perfect, the interior mostly new old stock parts, the drivetrain was freshened and assembled. After finalizing the build, the owner said the automatic shifter was locking up, every time you cranked the car the shifter froze. After the assembly the engine/ drivetrain dude failed to put new ground strap on the engine, the shifter became the ground circuit between the body and engine. The circuit was so hot it melted the bushing locking up the shifter. Later I owned a 72 Chevelle, came from the factory with 350 2 bbl. Automatic trans. As my short track driving adventure was coming to an end, I was in a junkyard and spied a 69 Hugger car, as I got closer, I realized it was a Z-28 car body beat to hell but complete, I bought the entire car engine, rearend, and trans for $500. Sold the body/ interior to Darrell Mobley for $500 with the goal of going limited racing. Freshen the engine, popped it in Deuce and off racing we went. I quickly realized the V-8 with two hundred more horsepower and 80 lbs. of nose weight crippled the Deuces handling package and just moved on to something else. Meanwhile the grocery getter was laying down. That sentence had duel meaning, the 350 had a 100,000 miles of hard life, and the other grocery getter had an affection for grocery boys. Both were on the way out. I took a few Sundays pulled the Deuce kicker and put in in the Chevelle. Needless to say, that lit the ole girl up. After installation I notice the trans not shifting right, a buddy looked at it and told me the shifter cable was junk looked like it had been against the exhaust. We installed the new one and the grocery getter was back in service. Shayla and I was washing cars one Sunday and I realized shifter was back at it, I pulled the cover cranked the car and the cable was red hot, the casing melted to the cable. After the Mustang issue I realized “Houston we have a ground Issue”. The deuce engine was a show piece Hugger orange trimmed to the nines as we had got in that kick of dressing engines, I painted all the motor mounts, chassis and frame, installed new rubber oem mounts. Factory mounts and chassis are E Coated 1-2 mils at best lends itself to good grounds, 11-15 mils of Centari Acylic enamel does not. I took the starter off cleaned both surfaces to bare steel, sand blasted the starter bolts and washers, ran a ground cable to the battery the replaced the shifter cable. This rectified the issue and became the norm on restorations going forward.

Deadly power of grounding circuits. Over the years we as NASCAR racers have lost more than our fair share of great drivers to a phenom known as stuck throttles. In a discussion with my dad one-time he chased the idea of a Daytona car, he said that just about every year somebody lost their life on the old road course, the thought of strapping someone in a car then losing them was always in your mind. Over the years that experience never softens. After losing Dale Earnhardt, I can only imagine how my dad felt when Fireball Roberts was killed. We had raced with Tiny Lund in Lake City a few weeks before his death in Talladega. The catastrophe with the Cooper Bros. and Don Williams hit home in the worst way. I could go on, but I have always said don’t let any racer die in vain, understand the loss and protect the next racers from the obvious. Three deadly crashes have always stuck out in my mind, in October of 1985 Richie Evans, May of 2000 Adam Petty and Kenny Irwin in October of 2000. Richie’s death was probably the first one I was at the track. I remember, one of the team members saying the throttle hung open, NASCAR officials raced to check every throttle, practice was not as important as the throttles, Steve Crowe, Buddy Bakers car chief was on a mission to be sure nothing was remotely close to the throttle.

Many teams at the time used a GM cable throttle. The cantilever style was an early GM design that went back as far as early 60’s and copied by many racers, the cable was introduced by Pontiac in 1963-65 with many Winston Cup teams choosing that product for simplicity. Flash forward to 1995 while racing at Hickory, NC, Metal Crafters updated Jimmy McClain’s LMSC with a new Townsend front clip. Jimmy’s team assembled the chassis and body headed to the track for the 1st race of the season. During the first practice the car was off the pace a second, Jimmy came in said the car was on a rail but slow, it appeared the throttle was only opening 3 quarters of the way, we all that was Jimmy’s fear level. We adjusted is cranked the engine and the throttle worked perfect, after a few laps Jimmy told the team the throttle was sticking, I was scanning them I motioned to bring him down to check it, as he stopped, we pulled the hood it was turning about 4 grand I grabbed the linkage and it melted my glove to it. We shut it down and by the time we got it in the stall the linkage worked freely with a half-melted glove on it. He started the engine, the linkage started smoking the carb safety wires were glowing, we immediately realized the linkage was serving as the ground. The LMSC world used a Howe type solid mount, anodized steel, bolted with 3-3/8 bolts to the block, 1- 3/8 bolt down through a pipe style mount on frame, the mid mounts bolted between the bellhousing and block with 6- 3/8 engine bolts. In theory totally grounded unless the frame has been painted with 11-15 mils of urethane enamel. The starter wire came through a solenoid direct from the battery, the only direct ground was directly through the accelerator linkage bolts in firewall through the firewall spot welds to a common ground bolt. We quickly raised the engine ground the paint off mounts changed the throttle linkage and qualified on the outside pole. That night I contacted every team Metal Crafters was associated with, Monday I contacted NASCAR and talked the ground issue through, as always, I felt NASCAR discounted the information. From that point on we always ran a common ground system that linked every component that required grounding to the battery ground.

We Addressed the An Issue but Not the One That Counted

On the way home from that early spring Hickory race nursing a burnt hand I looked at my daughter and said I know what’s causing the stuck throttles! I was working at CVCC in May of 2000 when Adam Petty got killed at New Hampshire Speedway. I heard the news, and my first thought was where is Shayla? I called her said pull over and listen as she parked, I sorted out how I was going to tell her. Adam and Austin frequented Mike Beams house when they were kids, Shayla was in generation of racer kids that were born in the late 1970’s early 1980’s, Lyndon Amick and Blaise was two years older, Adam was 4 months younger than Shayla, Austin was 2 years younger but racer kids none the less. As I told her the news the silence was the next level a racer enters as the mature. She was at the track when Neil Bonnett died, he had a hobby shop in our complex, 3 days later Rodney Orr a young man I built cars for, was killed at Daytona. Adam was different, different for me, for the racing community. As I gathered my thoughts I chased the reason, I talked to Kyle from time to time, Richard when I saw him, knew a number of the team members, and had connections to many of the crowd that surrounded Adam. I was writing articles for Racing Milestones at the time. I chased the stuck throttle concept the press was pushing, the idea that an accepted design could in fact lead to a deadly recurrence challenged my faith in what we do. I had been around a lot of great race assemblers, machines in the way they do things, they leave no stone unturned, but are systematic in the way they approach the machine they prepare. The system is never challenged until it fails in results. As crew chiefs make things faster systems mature/ change, as engineers evaluate factors of safety, things that appear obvious are never questioned. A stuck throttle on a Saturday racer falls into a rookie mistake, a stuck throttle on a NASCAR Cup car that kills a rising superstar moves beyond acceptable. Who is responsible? There is no doubt there will be another stuck throttle in NASCAR, but today’s fail safes are better than 2000. When I questioned the throttle linkage issue in Racing Milestones Magazine, I was passionate about Adam Petty’s death, just as passionate about Kenny Irwin in July of 2000. I was told shortly after the article hit in August of 2000, I would never write another NASCAR article, never been paid again to write since that article, NASCAR has the power to stop you from voicing a thought, just not the imagination to cure the problem before October when it becomes a talking point again. At the end of the day Adam/ May, Kenny/ July, Tony/ October, and Dale Sr in February 2001 all died of basilar skull fractures not the first by any means but there were many with basilar skull injuries that lived but never race again. I chased the throttle I could accept and could fix what caused the crash, I didn’t realize that the deaths were caused by something that needed to be addressed right away, and outside the car. After Dale’s wreck a NASCAR team looking into the death, sent me a copy of a memo written in the early 1960’s based on some Navy Crash info, the premise was that there was a set G Force on impact that challenged human bodies. The engineering white paper added that 75 g spike could kill a 75-percentile male, Dale Earnhardt’s size. The paper went on to say that a 100 mile an hour dead blow crash could easily spike 50+ g’s. Jet crash data proved that 70 g spike crashes turned their internal organs to mush. I asked my NASCAR contacts if NASCAR was in possession of the white paper long? White Paper data was accumulated in the 1950’s. No answer of course! Absorbing energy has been the plus’s and minus’ of American stock car, body, suspension and chassis that on impact absorbs then disperses energy. Engineers often apply basic physics that are associated in car crashes depending on the task, protect the car, protect the passenger. During the GM tech team years, I was asked how stiff do I feel a NASCAR chassis needs to be? My take has always been you only need to get the job done. Chassis flex is an engineer’s interpretation of weakness or failure. In an effort to fix the weakness it is easy to go past the point where energy can safely be absorbed or dissipated. Months before Dale’s death and months after Adam’s NASCAR mandated that the front frame snout be strengthened from .083 2×3 tube to .095. A consensus that stronger is better, many felt after looking at the car that the .095 frame weldment in fact was the point of impact, a point where the absorption of energy stopped, and everything contained in the super structure that could be challenged by a 75g spike was destroyed. As a collective, racers searched our minds with broken hearts, our lifestyle just killed the sports center of attraction and as in any tragedy somebody needed to identify the blame.