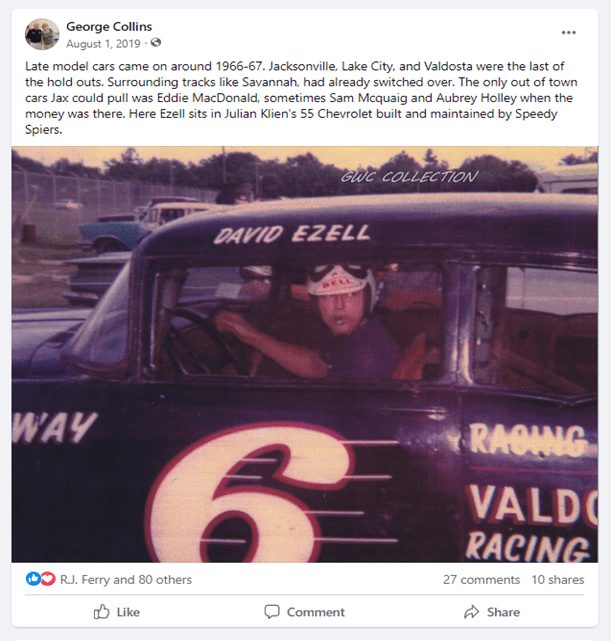

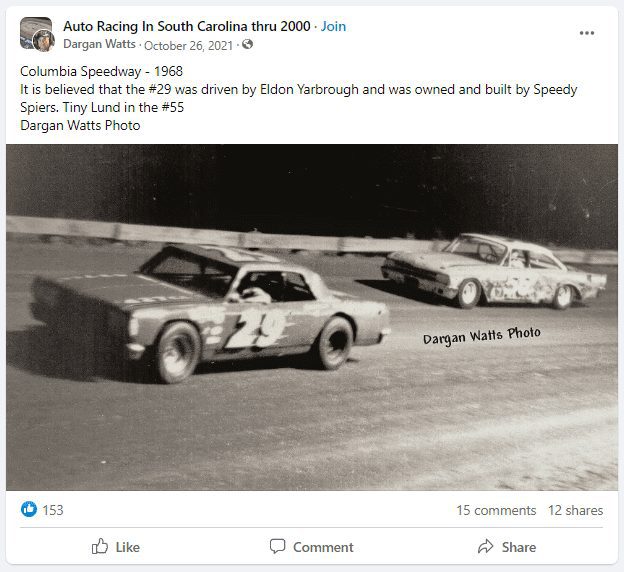

Bobby Allison took GM’s bait, caught a big fish, then put the bait on sale for racers everywhere, Bunkie Knudsen’s plan changed racing for the Saturday racers for the next 60 years. The first racing Chevelle I remember was Speedy Spiers 29 driven by several hot shoes at Jax’s Speedway Park. At the time David Ezell was dominating in a #6 55 Chevy. Had one of the infamous Julian Klein bounties on him, up to about a $1000 at the time. Speedy built a 1965 Chevelle, brought in a 26-year-old Eldon Yarbrough, “Leroy’s younger brother”, from Columbia, SC to challenge David. Halfway through the feature David kept pinching Eldon down as they came out of 4 Eldon made the move of the ages, turned David sideways and carried him the length of the front stretch. As they turned down into the corner, he let David go, as they powered off turn 2 Eldon sealed the deal. Everybody in the grandstands was sold the Chevelle was the answer.

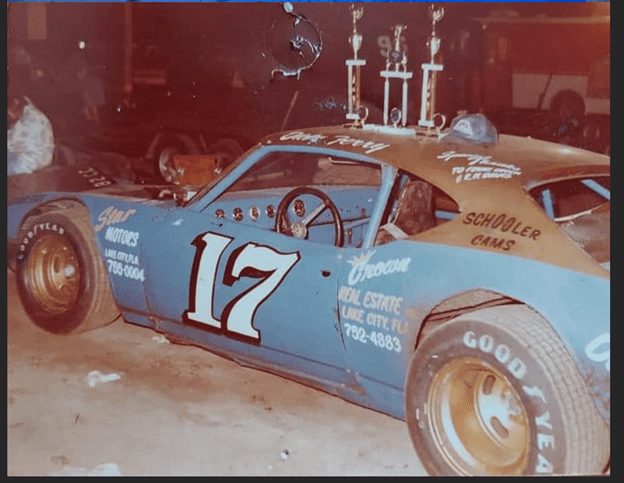

Later that year my dad and I went to Hialeah Speedway in South Florida, 20 of the fastest asphalt late models in the country, every car was channeled 64/65 Chevelle’s they looked like they were 2 inches off the ground, big hood scoops, and on a rail. To me there was no doubt that the 64/65 Chevelles were the future. As the 1973 season ended Wally and Dickie (RJ) Ferry started building a 1965 Chevelle, I remember checking out the progress on the car, the bare chassis setting on 6 inch wooden blocks, random parts appearing day by day, Chevy truck arms, Franklin Q/C, stockcar products spindles, Moog steering parts, I remember pulling a Vega steering box off an old burned car we bought and giving it to Dickie, he rebuilt the 16 to 1 box, it had a 5 inch pitman arm and idler arm combination straight up Chevelle geometry. The 65 put Dickie on the path to winning and gave me the opportunity to study up close the front steer sportsman, with big springs/ truck arms. Dickie’ team followed the 65 with a 69 Chevelle sportsman style car that dominated 1974-78.

As the NDRA came on the scene exotic tube chassis and bodies started to appear and the NASCAR late model sportsman car as an outlaw dirt racer disappeared. Many times since then, Dickie and I have spoken about his Chevelles, we both look back and say that if we built the Chevelles with what we know now. Wally always felt Dickie needed to mature the Chevelle program, Wally loved being dominant. I didn’t have a dog in the fight, but the 1St generation of the Snow Brother’s Natural Lite chassis was challenged at best, but as always great workmanship, a Howe copy front end, engineering/ design issues, I caught hell for my opinions on that ride, but at that point in time my direction was away from Macclenny and on to NC. After Albert Water’s Lake City Speedway closed down in 1978, my mind was already in motion to learn as much as I could about the NASCAR sportsman, Grand National, Winston Cup cars. Art Reno’s breakdown in Macclenny in February 1977 gave me the connection from point A to point B.

Rear Steer vs Front Steer

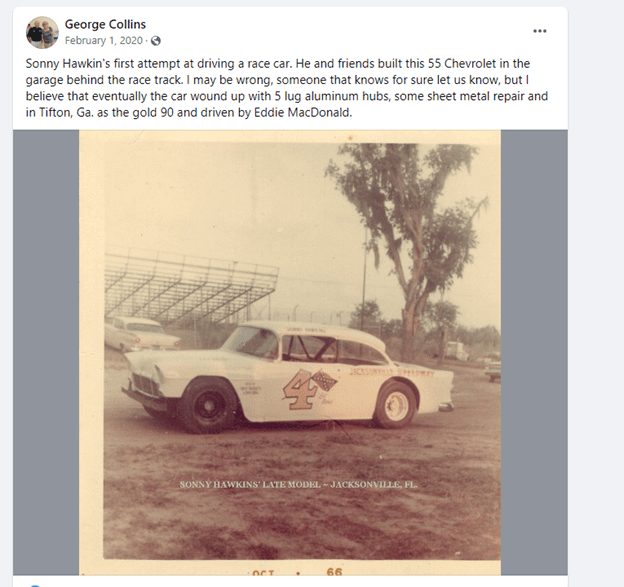

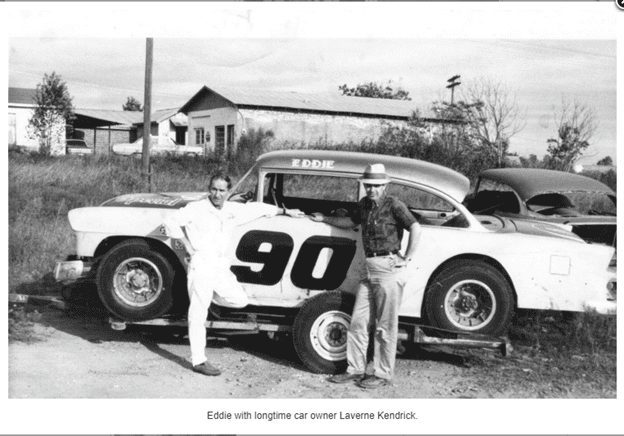

In the early days Holman Moody controlled Ford’s NASCAR side of racing. As the story goes just about every great race fabricator, machinist, chassis wizard, and engine builder in NASCAR was a product of Holman Moody. Over the years I have had a lot of great racing talent work for me, I can tell you from the heart “great talent will succeed in spite of you not because of you”! I always felt that taking credit for somebody else’s talent is a little self-absorbing. I as well as hundreds of race shops have given folks a place to learn, get acquainted with the cars, equipment, procedures, and launch their imagination. My first encounter with Holman Moody as a subject matter was thru Sonny Hawkins. Sonny had a race car shop on the west side of Jacksonville, FL, later he sold it to Tommy Riggins. My dad in his search for information befriended Sonny, whose history included time spent in LA-LA Land (Charlotte) working for Holman Moody, with random business ties to Tiger Tom Pistone. In the early seventies my dad speculated on buying a 55 Chevy Sonny had for sale. The car was later purchased by Laverne Kendricks and driven by Eddie McDonald.

The rumor was the chassis was built in the Carolinas, super clean really light, when dad was chasing that rabbit it had Franklin Q/C Wide 5’s, magnesium wheels, Eddie won probably 50 races, rumors were that the car was passed on to Rance Phillips to start his career, Eddie told me they cut the roll cage off the chassis and built Laverne’s first gray and gold Chevelle. Racers will pull your leg so there it is. The irony of this build was it built on a Ford chassis, rear steer leaf springs, to support Eddie’ story Laverne’s first 64 Chevelle was a Ford chassis also.

Sonny had this real approach to racing, “learn to drive”, “learn to race”, “learn to win”, that was his best advice and I have passed on that concept on to racers for 50 years. His business model included, selling cars, selling parts, repairs, some new construction, sourcing parts, chassis set-up track support, I later understood the income stream and successfully implemented the business model in an atmosphere with the racing income to support it, Jacksonville, Fl was not the place. Dad visited Sonny a lot and I was right there soaking it in. Sonny was a disciple of Holman Moody; my dad debated the front steer/ rear steer direction that Sonny embraced. Sonny’s perfect world had all cars on Ford rear steer chassis and/or NC generated chassis, his defense was nobody was winning with Chevelle chassis’. Technically he was right, but the reality was coming, and Holman Moody wasn’t privileged to Bunkie Knudsen’s plan. Bunkies plan was slow in coming to the racetrack. In 1966 Bobby Allison built his first 1964 Chevelle with tech support from the GM Tech center, Bunkies marketing team were instructed to make Bobby Allison’s Chevelle a household name, every magazine in the country carried the story, David against Goliath, but the bottom line was to fuel the imagination of the Saturday night racer. Bobby surrounded himself with racers, sourced parts and by 1970 had the first kit style parts list. A crude but effective chassis drawing with challenged measurements, and parts list with a phone number to order everything from BA in Hueytown, AL. To make this plan work Bobby and the Alabama Gang raced anywhere, anytime, winning all along the way. Car builders had a product line and a clientele that read the performance car/hot rod funny books. Front steer car builders like Mike Laughlin and Ronnie Hopkins started building 64-72 Chevelles and 70-81 Camaros. Saturday night racers started building front steer NASCAR sportsman and Grand American cars. Bobby Allison and Tiny Lund carried the banner and logged up the wins. On the other side of the coin, Eddie Pagan had developed a new fabricated rear steer front clip for Holman Moody, as trick as the innovative front clip was, Holman Moody without Ford’s support was spinning without control, in 1972, Ralph Moody’s stock in Holman Moody is bought back by the company, and he goes on to other racing teams. The company name remains the same. To clear away old race cars, the company has the first series of auctions. Holman Moody sells all nine GTs, some Can Am cars, Thunderbolt drag cars, and some retired stock cars to make room for new projects. For NASCAR Holman Moody (Tommy Turner) would continue to build engines for Woods Brothers/ David Pearson. Holman instructed Hutch to copy the clip, they did and started Hutchinson-Pagan. Holman Moody was the self-proclaimed sole source for 9” ford floaters, speedway and short track floater hubs and snouts, 2-piece front spindles, draglinks, and fuel cell tops. The plan was to continue manufacturing, eliminate the inhouse race cars and laid off the car fabrication workforce. I worked for Hutch the end of 1985, a quick internship to learn how to manufacture chassis, he told me once that the hoarded up 20 cars worth of parts, most were thrown over the fence and retrieved at dark after Holman Moody was closed. Two of the first cars were sold to Junie Dunleavy from Richmond, VA, early in 1973. One of those cars was the car we ended up with through the Art Reno Adventure. These monsters were a 115-inch wheelbase, 64-inch tread with cars and a minimum wt. of 3750 lbs. Most of the modern era, post 1960, US automotive designs included front suspensions that used 60% unequal length control arms, non-parallel with 2-5 % anti dive, 1* camber gain per inch, 1* caster gain per inch. The front and rear steer cars both follow that design of mechanics in motion. The difference is an inherited design flaw in a phenomenon called bump steer or roll steer. The rear steer steering apparatus is under the engine challenging the geometry. Oil system technology requires larger pumps, specific oil line location and wider pans. Lower ride heights, improved aero, challenges how high or low the center drag links must be, lower the draglink lower the spindle steering arm has to be. The bump steer is corrected with machined drops, longer the drop the bigger chance of flex and failure. Both cars have a certain amount of Ackerman gain, but the rear steer configuration has more inherited gain than the front steer geometry. The rear steer folks endorsed that flaw as a superior but needed 20 HP to overcome the genius of the design. I was paid by GM to map the Banjo rear steer Bud 11 car Darrel Waltrip won 13 races with. The car won 7 in 1984, 3 in 1985, and 3 in 1986. After mapping the front end, we documented that the car had .100 bump out right,.200 bump out left, per inch of travel, Akerman gain per 10 degrees of steering was .200. Rear steers also can lead the front suspension, the 11-car wheelbase was 111” on the left ,109.5” on the right. The front clip was mounted 1 inch off center, after reviewing the shock travel notes from various competitions, the car on entry had almost .500 toe out in the left, .250 toe out in the right. ¾ of an inch shock travel total/ 10* steering to the left. Now scrub kills HP but it complements drive feel, in fact the 11-car turned in almost on its own, tire wear was consistent. How did DW win with that much parasitic scrub? Jr Johnson’s engine room through 1986 was consistently 50 to 75 HP better than most of the other cars. Our conclusion DW the driver exerted less energy throughout the race and was fresher to race at the end. The teams that had cars with the old school challenged geometry similar to DW’s with 50 less HP were back markers. Rear steer and front steer teams with corrected geometry could have 50 less HP could race equal to or slightly slower (Blue Max, Hendricks, Baker/ Schiff, Curb). Long run DW’s 11 stayed consistently 3 tenths better in a fuel run. Bakers team down 50 HP with the same basic setup and frontend geometry were lapped within the first fuel run. Earnhardt was a stronger driver, but Childress engines were conservative at best (20 to 30 hp off), they were fishing for championships with better bait (Earnhardt). On any given day the 3-car crew could roll back the parasitic scrub, tune the steering geometry, back the caster out, tune the lead in the front end and let Dale be Dale, they could beat DW. DW domination days were over, Jr’s days were numbered with the rear steer cars. The front steer cars were HP positive, most front steer teams making close to 100 hp over rear steer compliant engines. The chassis alignment as far as caster, camber, lead, could easily be duplicated, Ackerman could be engineered in or out based on the magic you believed in, the lead could be adjusted with eccentrics, and a-arms. Bump steer/ roll steer could go to zero bump steer, zero Ackerman gain, increase steering axis inclination from 8* to 11*, and eliminate the majority of geometry induced parasitic drag all within the boundaries of the rules. To enhance driver feel that relied on the forces applied through steering geometry, teams found increasing static camber gave drivers the steering feel without creating scrub. Anti dive/ caster gain/ static caster are all self-aligning effects, castors by design want to align with drag loads pulling the wheel, turn the wheel around and it automatically wants to turn around in motion, this applied force in auto fronts ends is caster and is controlled by tying both spindles together with steering mechanism. Rear steer forces are in compression, front steers are in tension, both have percentage of load error, front steers historically move less under load, but toe must be compensated for these loads. In 1985 at Charlotte Mike Beam brought out a new Laughlin car for the King, the 009 car was off the top speed, tire temps showed camber issues, Beam showed me the sheets I suggested it wasn’t camber it was toe out. Tire loads rolling can easily be interoperated as camber rather than toe. I told Mike it is an easy fix; he measured the toe it was 0 dead up, I told him that the bump/ Ackerman in dynamic situations could easily toe the girl out. He hadn’t mapped the bump or Ackerman but did show a gain issue from left to right at 20* on front end plates. He finally gave in. My solution was not to worry about measurements but tune to the stopwatch. We would go to pit road, Beam was on left, Kelly Hunt was on left, one turn on tie rod per stop. First run King was faster but didn’t feel change, we continued, Beam asked where should we stop, my experience with road cars says we stop when the King says it is darting and or we fall off on speed. After about 5 stops Richard said I don’t know what you are doing but is driving off one front wheel than the other. I suggested going back one round or until the car felt like Richard wanted, then throw on a new set let the King run a hot lap on stickers. Richard was in the top 15 on time charts, qualified 10th ran in the top 5 most of the day. After practice we measured the static toe at .500” toed in, and we all knew that a ½ inch of toe in wasn’t mechanically correct as standards go, but the consensus was we tuned the alignment to go fast, and we needed to ignore what we think till we get back home. Richard agreed after the tire sheet showed perfect temps. Go Figure! After the race the front end was mapped, the car had bump steer out of .100” per inch of travel, left and right symmetrically, with a disparity in the Ackerman gain of 2 degrees in 15 about .250” toe out as the wheels turned. To fix the bump steer the inner pivots were moved up .250”, to fix the steering disparity the steering pivot was moved outward from the spindle center, .100” on left, .075” on right. This gave us zero bump, zero steering gain, with zero toe at static, in total dynamic travel, toe was .065” bumped out. At Atlanta next race for the 009 car Richard qualified 5th finished 10th. From an engineering standpoint in the early days there was a lot of cut and try. From the manufacturing side/ car builders chased a product line and I fall into that category. Once you establish a direction you become a specialist of the product you choose to build, chassis builders in the early days of NASCAR from the short track sportsman/ late model stockcar cars to Winston Cup cars from 1972 to 2012 created a platform for car builders to develop, they hung bodies, perfected suspensions, the “crew chiefs” set the agenda and design choices. Teams capable of building chassis in house developed the resources to do so. In the early nineties two things happened, new teams started to buy new turnkey cars from reputable car builders, the second was an insurgence of engineers to chase the history and document the fingerprints of accepted dynamics. Technicians like myself, worked with engineers to bring them up to speed on what we had been doing for 20 years prior and how to communicate with the old school dudes. Car owners let crew chiefs chase the product of the day directions, that includes but is not limited to, chassis, components, 3rd party body builders, shocks, springs, I have seen team owners hire a crew chief and his refugees, and by dark they have put in motion changing everything but the building color. In the mid 1980’s the debate of rear steer vs front steer, I saw a crew chief win a race come in the shop the next day cut 5 front clips off of current cars and off to Laughlin’s they went. For 1986 Mike Beam converted a rear steer car to a front steer by changing the clip, the clip was a new generation drop snout geometry. Ron Bouchard really wanted the new generation clip we took both cars to Atlanta to test, 009 a proven car and 005 a converted Petty dinosaur. Bouchard couldn’t tell the difference, the 009 conventional clip car was more consistent, Bouchard was a Laughlin disciple and convinced the dropped snout was by far the better choice, the stopwatch didn’t tell that tale. After the test Mike Beam told us to prep 009 for Atlanta, Kelly Hunt, Steve Wilson, Scott Beam, Disassembled and reassembled the car for Atlanta, just like the last Atlanta race of 1985. We got to the track unloaded, passed the inspection dance, and rolled out on pit road for practice. Ron Bouchard flew in walked up to car asked which car it was, we told him 009, he said that is not the car he wanted. After dragging around ½ way thru practice to get in car he made about 5 laps and declared a vibration we chased until he parked the car 140 laps into the race, finishing 40th he told the press we lost a clutch he thought. Mike Beam left the team shortly after. In 1987 Mike ended up with Bahari, driver Michael Waltrip, owners Dick Bahre, Lawrence Harry, and Chuck Rider. Dick Bahre owned a fleet of dinosaurs; Mike got a Pontiac deal and Chuck Rider bought 2 new Laughlin cars. Michael Waltrip, drove the Bahre fleet of 14 cars and only liked 2 cars while the others collected dust. I met with Chuck Rider and Richmond Gage to hang a couple of bodies paid for by Pontiac. Chuck Rider was quick to put a value on the fleet, I had to break the news that without major changes to the roll cages 6 of the14 cars were not even legal for 1988. Show car fleet at best, after major surgery, we built 2 show cars, and 2 race cars for Bahari. The point of this discussion is that teams in that period of time owned up to 14 cars, each a snowflake, hand built, an accumulation of parts, and at best a disposable body/chassis. Monkey see monkey do, Rusty wins on Sunday, Mike Laughlin leaks the combination to each crew chief on the deal, the deal being having enough money to chase the trick of the day. By 1990 engineers slowed the hap hazard chassis choices, mapping successful chassis/ bodies/ engines, turned into a process of design. Each direction had a reason, R&D was developed from a common baseline, the freedom to design and tune still existed but engineering was now a partner in the process.

Opinion: Ron Bouchard was a disappointment as a driver, in 1986 he had moved into the auto dealership ownership realm, his importance in NASCAR was to represent the New England modified contingent, and his talent was limited at best in Winston Cup racing. Some compared him to Buddy Baker. I appreciated the comparison, but Ron was never even capable of winning even 19 races in 40 years, just like Baker couldn’t win 200 in his 40-year career. After a rain delay, Ron purposely crashed our new car at Darlington, so he wouldn’t miss his plane. I was finished with Ron Bouchard that day. A year later Ron was driving Hoss Ellington car, Runt Pittman asked me about our experience with the “vibration”. I told him Ron was the “vibration” he doesn’t like the Hutchinson/ Pagan cars you have, but don’t worry he will crash everyone you own, till you buy new Laughlin trick of the day cars! After 5 races of and 3 DNQ’s the Hoss Ellington “vibration” disappeared with Brett Bodine as driver.

Note: In 1987 Hendricks created a dream team for DW it was best of the best, I was invited to the first meeting of the employees, 3 teams of refugees were in the house, Mike Beam’s, Gary Dehart’s, Waddell Wilson’s, Wilson was in control. As I listened to DW talk about how great the cars at Hendricks were compared to Jr. Johnsons, I turned to Mike Beam, Gary Dehart, and Eddie Jones, DW’s Busch crew chief and asked, DW does know this is going to be a front steer shop? They all laughed! Waddell told me I would be working in the body shop with his two sons, I was asked to interview to work in the chassis shop with Mike Beam. Gary Dehart had never worked with us so my reputation as a painter got me back in the body shop. After meeting with Waddell, I told him thanks but no thanks, I would chase my own rabbit. I felt the dream team had issues with ego’s bigger than the product, I didn’t have an ego big enough to fail with them.