Below is a 2020 proposal prepared by our team for Motlow Community College in TN, it includes an updated version of the 1996 CVCC proposal. The biggest difference is the Modeling/ Computer Aided Drawing aspects. My dad and uncle were draftsman, by 1984 when I made it to the game, the best fabricators were the best layout men, full scale, with every trick layout tool available. The vision and interpretation of what they saw was in their hard head instead of a hard drive. Today our design process is enhanced by CAD software, every component is part of a design process that strengthens the overall understanding of the part, the associated imagination, the fabrication process, and craftsmen related skills still exists but the overall confidence in the part is more consistent.

Performance Vehicle Fabrication

Career in a Year

The Motlow Performance Vehicle Fabrication Career in a Year is a multilevel program with an emphasis on skills necessary to design, develop, fabricate, assemble and implement innovative mobility solutions. Students will learn to apply skills and design methodology used in the performance vehicle industry. The Performance Vehicle Fabrication Program includes twelve areas of skills specific instruction. Each area of instruction corresponds and builds with skills learned in previous classes to develop a team specific collegiate design project. The designated sequence of class’s are facilitated so students gain valuable experience in line with projects that complement the performance vehicle design process. The program consists of eight- week segments, four contact hours per day, and five days per week Open lab curriculum are designed to give students extra access to equipment for fine tuning skills and machine operation. Trained in hybrid labs with ultramodern equipment, CAD (Computer Aided Design) software, jigs and fixtures, student technicians will build confidence in actual industry endorsed collegiate design environments with real time deadlines and goals. Program instructors with extensive experience in automotive and performance vehicle design will facilitate a series of design specific training exercises in tune with the needs of the vehicle manufacturing industry preparing the workforce for Tennessee. The program will be centered around Collegiate Design teaching aids (Formula SAE) with each student technician personally maturing their skills, expanding their knowledge and confidence as collegiate design team members with the objective to fill key positions in the automotive industry.

The eight-week format allows a student to complete the full program in 48 weeks 960 contact hours with a Certificate in each of the twelve areas of instruction. From an administrative viewpoint the program can process 20 students max per class, 2 classes per year, 2 instructors per class (10 students per instructor) Morning class 8AM to 12 PM, Afternoon Class 1PM to 5PM, 40 students per year. With 1.06 FTE @ $9582 per FTE (2018 TN Calculations) would generate $10156 per student and projected tuition income of $405,276.80. (full load) In addition, the facility will be capable of facilitating short term equipment specific classes, 2 days 6 hours @ day (metal shaping, powder coating, chassis dynamics, welding) (10 per class@ $500= $5000 per class) 4 to 8 weekend classes per year. Additional income of $20,000 to $40,000 per year. This model has been very successful in the Bobby Isaac Motorsports Program and THEC approved for the Metalcraft Skill Center in Crossville, TN (closed in 2010).

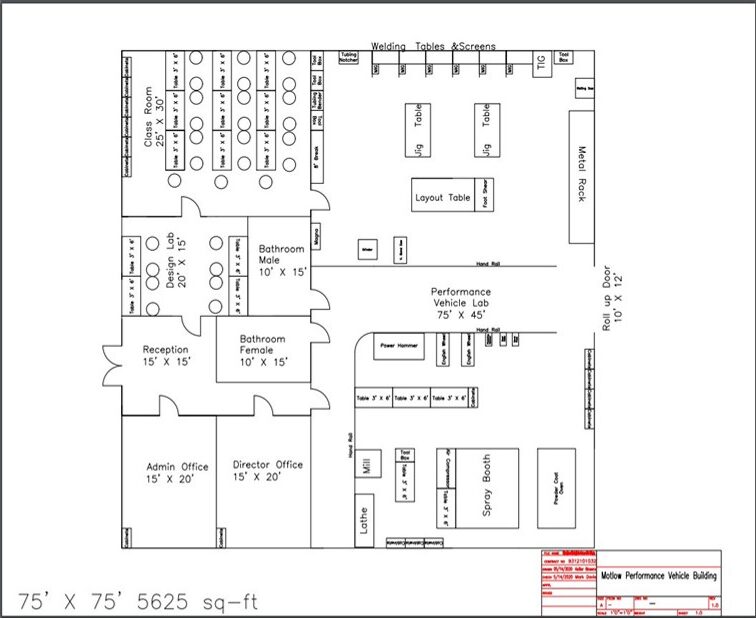

Included in this document are startup equipment, materials, and components to build 2 FSAE turnkey teaching aides (1 per class). The equipment estimates reflect no education discounts (most offer 10%). The fabrication equipment listed is industry proven and has a duty cycle in training programs of 20 years, with welders and computers timed out in 5 to 7 years. The material list includes teaching materials, and materials used in prototype construction. Most vehicle programs implement a student course fee of $50 per class per student ($12000 @ 20) to cover materials used in the training process. The building concept 75’x 75’ 5625 sq. Ft. model is an open lab design out using handrails as lab dividers. This facility is designed to service 20 students max per class. The structural metal building design lends itself to linear expansion as program matures or the need for advanced Vehicle Design Engineering programs.

The strength of the program depends on the staff and their experience with the performance automotive industry. The automotive industry is in an upswing in

Tennessee and the state government are aggressive in maturing an automotive confident workforce.

Executive Director: An executive director would complement the program lobbying industry and government with funding for program and facility expansion. The automotive industry has built in funding to mature job specific employees with equipment specific skills. The industry also has research specific needs that are confused in non-automotive centered programs. To mature this direction of industry an executive director privileged to the automotive industry needs knowledge of aggressive government automotive directions and funding would strengthen the Motlow Performance Vehicle Design programs.

Lead Instructor: The lead instructor must have collegiate design experience to would manage day to day training programs, must have experience in the performance industry, proficient in the industry related skills, setting up skills/ equipment specific labs, have experience in facilitating classes, developing curriculum, managing program budgets, managing student projects, teaching multiple classes, facilitate collegiate design competition travel/ lodging with ability to train all future lead instructors and instructors for program expansion to multiple campus’.

Instructor: Instructors would have experience in the performance industry, proficient in industry related skills, setting up skills/ equipment specific labs.

Administrative Assistant: An administrative assistant 7 experience within the TBR/THEC system. Manage day to day office and reception, facilitate student tours, facilitate business for program according to State, THEC, and University guidelines, generate/ update business expenditures for programs, grants, student projects, and research. This position must maintain current knowledge of pertinent University, State, and Federal Laws and guidelines. Accurate analysis of policies and guidelines; accurate analysis of student accounts and general receivables with respect to these laws, guidelines and policies; and coordination with other campus offices is essential. This position must be able to communicate effectively with students, parents, faculty/staff, and third parties as allowable within FERPA and other privacy law restrictions.

Equipment, Components, and Teaching Material for Motlow Performance Vehicle Fabrication Program Start up.

| Mittler Brothers* | Total | $59,616.65 |

| FASTENAL* | Total | $1,631.07 |

| Granger* | Total | $19,277.16 |

| HARBOR Freight | Total | $1,439.94 |

| Baileigh Industrial* | Total | $32,070.00 |

| Air Compressors Direct | Total | $9,627.48 |

| Columbia Coatings* | Total | $25,929.99 |

| MATCO TOOLS* | Total | $9,410.70 |

| Landmark Truck* | Total | $15,500.00 |

| Dell Computers* | Total | $24,894.00 |

| MSC Industrial | Total | $4,116.01 |

| Trick Tools* | Total | $12,017.00 |

| Interion | Total | $4,770.00 |

| Lincoln Welders* | Total | $22,529.00 |

| TOTAL Equipment | $242,829.00 | |

| TOTAL Materials | $6,574.02 | |

| TOTAL Components | $19,800.86 | |

| TOTAL Startup | $269,203.88 |

PERFORMANCE VEHICLE FABRICATION

SYLLABUS

Eight-week Monday — Wednesday — Friday 96 Contact hours

Course Description:

96-hour class that introduces basic fabrication procedures and skills used in custom auto construction, including equipment operation, pattern layout and production, basic bracketry, and component mounting procedures.

Course Objective:

To build confidence in standard layout and part development.

Material and Tools:

Notebook, 12’ tape measure, combination square, right and left offset aviation snips, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading system is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

This program is designed to give students maximum exposure to the equipment and procedures used in the motorsport and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus as anytime as they see fit.

PERFORMANCE WELDING

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact Hours

Course Description:

64-hour class that introduces MIG and TIG welding procedures used in the custom automotive industry. Light tubing, sheet metal, aluminum, stainless and chassis components

Course Objective:

To become proficient in MIG and TIG welding procedures associated with custom fabrication.

Material and Tools:

Notebook, welding helmet, welding gloves, long sleeve shirt, eye and ear protection

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

PERFROMANCD AND CUSTOM PARTS MACHINING

SYLLABUS

Eight-week Monday – Wednesday – Friday 96 Contact Hours

Course Description:

96-hour class that is designed to introduce basic machine operations. Lathes, mills, drilling and tapping techniques for custom part development.

Course Objective:

To build confidence in standard layout and part development using machining processes.

Material and Tools:

Notebook, 12’ tape measure, 12” crescent wrench, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM MODELING

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact hours

Course Description:

64-hour class that includes multi-dimension modeling and documentation, skill in layout, part design, CAD-CAM

Course Objective:

To establish the ability to take mental images to computer aided drawings.

Material and Tools:

Notebook, 12’ tape measure, 12” crescent wrench, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

PERFORMANCE CHASSIS CONSTRUCTION

SYLLABUS

Eight-week Monday – Wednesday – Friday 96 Contact Hours

Course Description:

96-hour class that introduces chassis layout and construction techniques used in the custom, hot rod and performance industry. Includes engine and drive train placement, suspension component placement, modular construction.

Course Objective:

To learn proper construction, layout techniques used to build custom chassis and components.

Material and Tools:

Notebook, 12’ tape measure, combination square, right and left offset aviation ships, 12” crescent wrench, welding helmet, welding gloves, long sleeve shirt, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

PERFORMANCE CHASSIS DYNAMICS

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact hours

Course Description:

64-hour class that introduces chassis design theories, component design, alignment procedures, performance handling and chassis balancing.

Course Objective:

To learn basic design and engineering theories associated with chassis design.

Material and Tools:

Notebook, 12’ tape measure, 12” crescent wrench, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM METAL SHAPING

SYLLABUS

Eight-week Monday – Wednesday – Friday 96 Contact Hours

Course Description:

96-hour class that introduces basic metal shaping skills from bag and mallet to power hammer shrinking techniques, stretching techniques, pattern development, and panel reading.

Course Objective:

To learn the different methods used to introduce shape into metal panels.

Material and Tools:

Notebook, 12’ tape measure, combination square, right and left offset aviation snips, eye and ear protection, welding gloves.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM PANEL FINISHING

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact hours

Course Description:

64-hour class designed to introduce metal shapers to metal finishing and welding procedures and necessary in panel development.

Course Objective:

To take learned metal shaping procedures into panel development.

Material and Tools:

Notebook, 12’ tape measure, combination square, right and left aviation snips, welding helmet, welding gloves, long sleeve shirt, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

PERFORMANCE PART AND EQUIPMENT MANUFACTURING

SYLLABUS

Eight-week Monday – Wednesday – Friday 96 Contact Hours

Course Description:

96-hour class that introduces lean manufacturing procedures, production and project planning, material acquisition, job costing, package and shipping.

Course Objective:

To understand multiple manufacturing

Material and Tools:

Notebook, 12’ table measure, combination square, right and left offset aviation snips, 12” crescent wrench, welding helmet, welding gloves, long sleeve shirt, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

PERFORMANCE PARTS DISTRIBUTION

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact hours

Course Description:

64-hour class that introduces the parts distribution network, pricing, marketing, design and testing and retail distribution.

Course Objective:

To learn how to distribute parts and products through current distribution networks.

Material and Tools:

Notebook

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM BODY FABRICATION

SYLLABUS

Eight-week Monday – Wednesday – Friday 96 Contact Hours

Course Description:

96-hour class that takes custom fabrication, metal shaping, and metal finishing techniques in to body fabrication. Student technicians prepare chassis and components for body assemble, line up structural body panels and interior treatments for panel development.

Course Objective:

To take associated skills and build, locate and hang the exterior body panels associated with custom vehicle fabrication.

Material and Tools:

Notebook, 12’ table measure, combination square, right and left offset aviation snips, 12” crescent wrench, welding helmet, welding gloves, long sleeve shirt, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM PANEL DEVELOPMENT

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact hours

Course Description:

64-hour class that takes body substructures and incorporates finalized panels to finish body development, mounting panels, bracketry, trim, interior crush panels and other related components.

Course Objective:

To build confidence in exterior panel construction and design.

Material and Tools:

Notebook, 12’ table measure, combination square, right and left offset aviation snips, 12” crescent wrench, welding helmet, welding gloves, long sleeve shirt, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM VEHICLE REFINISHING TECHNIQUES

SYLLABUS

Eight-week Monday – Wednesday – Friday 96 Contact Hours

Course Description:

96-hour comprehensive course on performance vehicle preparation and refinishing. This course is designed to establish refinishing disciplines for custom fabricated parts, panels, body, interiors and chassis.

Course Objective:

To understand the refinishing process associated with complete vehicle development.

Material and Tools:

Notebook, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM BATCH POWER COATING

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact hours

Course Description:

64-hour class to introduce student technicians to cleaning processes, mechanical preparation techniques, application methods, and curing processes used in custom power application.

Course Objective:

To understand the process used in custom powder coating.

Material and Tools:

Notebook, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM ASSEMBLY PROCEDURES

SYLLABUS

Eight-week Monday – Wednesday – Friday 96 Contact Hours

Course Description:

96-hour class to cover final assembly techniques used in high end performance vehicles, chassis assembly, brakes, drivetrain, alignment, interior treatments, body, system instillation and other related components.

Course Objective:

To learn the proper assembly methods necessary to produce custom vehicles.

Material and Tools:

Notebook, 12’ table measure, combination square, right and left offset aviation snips, 12” crescent wrench, welding helmet, welding gloves, long sleeve shirt, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.

CUSTOM WIRING AND PLUMBING

SYLLABUS

Eight-week Tuesday – Thursday 64 Contact hours

Course Description:

64-hour comprehensive class that plumbs brakes, fuel system, oil system, gauges, custom line construction, wiring covers ignition, lighting, gauges, panels, interior systems and other related components.

Course Objective:

To learn the proper standards in plumbing and wiring for custom application vehicles.

Material and Tools:

Notebook, 12’ table measure, combination square, right and left offset aviation snips, 12” crescent wrench, welding helmet, welding gloves, long sleeve shirt, eye and ear protection.

Evaluation:

Experience, confidence and work ethics play a big part in the success of technicians in the motorsports and performance industry. Each technician will be evaluated on the degree of experience, knowledge and attitude. 90% of their grade will be based on lab performance. Grading systems is as follows: A = 90 – 100, B = 80 – 90, C = 70 – 80, D = 60 – 70. Students will receive performance certificates based on their overall grade.

Attendance Policy:

The fast pace of the classes and the real-life training environment make it critical that students attend each class. If excessive absences occur, the instructors may suggest that the student retake the class.

Message to Student:

The program is designed to give students maximum exposure to the equipment and procedures used in the motorsports and performance industry. Your level of experience and confidence is directly dependent on your thirst for knowledge.

The instructors have the right to change the syllabus at any time as they see fit.