I was in LA LA land (Mooresville, NC) vested in a new business, a business model my dad and I had critiqued from the Sonny Hawkins days. As I matured the Motorsports Fabrication business, dad studied the product the motorsports industry was pushing forward. To him as a purist in autobody fabrication the metal was more important than the product the industry was producing. Shortly into the new adventure, the NASCAR body building world started a transition, and to address that direction we focused on metal shaping equipment with specific skills. Dad reintroduced the racing industry with a 44” version of the John Glover English Wheel. Inside the Winston Cup circle in 1986, the workforce contingent was divided into 2 groups, the old school racers that had a history of racing/winning, with the this is how we have always done it mentality and a new group of skilled craftsmen that required explanation for every plan of action. The second group accepted focused instruction as a strength. My Dad and I fell in the second group, dad drove the concept of equipment specific short-term skills training, accepting the concept that once you reach a level of ability and confidence you can accept a given direction. As we moved into our first adventure into short term skills training, we reached out to North Carolina for their blessing to teach. The result from the NC Higher Education was telling at best, the letter was a waiver stating that personal development in the form of skills, topic, or equipment specific training related to hobby centered industries were exempt from any NC Higher Education regulations and guidelines. That letter of exemption from the NC Higher Education was in place until 2005. The irony of this exemption matured when motorsports became one of the top 10 industry employers in the state. The primary focus of the Motorsports Training Center was skills specific personal development training. Most of the students were racers, talent driven, looking to orient themselves with the NASCAR motorsports industry as employees. Many walked in the door without a chance and walked out the door valuable employees. We quickly developed a reputation of matching skilled craftsmen to teams that had positions with specific skills to fill. By 1991 we had placed over 200 race technicians into the industry. The overlap between the Motorsports Fabrication and the Motorsports Training Center allowed students to experience the workings of a real race shop, building cars, racing, selling parts and equipment. The two business’ quickly became a sought-after entity. In 1989 Humpy Wheeler announced the birth of the Sportsman Series, Motorsports Fabrication stepped up to retro build a few NASCAR Busch Car into Sportsman cars. This led to the first house car for the business. As fall approached the plan was to build a new Sportsman car to rent and or sell. A rental contract was quickly signed that included the two races at Charlotte for Doug Didero a young Oswego super modified hot shoe from New London, Canada. Doug was sponsored by Bob Raynor, a printed media mogul. After the 1989 races the Canadian cartel wanted to expand the relationship to the Busch series so the Sportsman house car was sold to Tom Sherrill.

Tom Sherrill was a retired Air Force IT Specialist that worked for Duke Power, 48 years old and a rookie racer. Tom’s racing program was facilitated by Motorsports Fabrication with Tom as a primary investor in the race services program at our facility, that included GC Campbell’s LMSC program and a number of race services. The 1990 program for Doug included 3 Busch Grand National races, Hickory, Loudon, and Martinsville. The Motorsports Training Center moved into a new 2000 square dedicated training area for 1990 with the Motorsport Fabrication occupying the adjoining 5000 square ft race facility. As the Motor Training Center grew the question of who was the flea and who was the dog caused tension between my dad and me. All the facility leases and utilities responsibility were Motorsports Fabrication’s, but the Motorsports Training Center was a growing profit center that was facilitated by my dad and mom, the issue was never about the funding, it was about when I went to lunch, where and what I eat, basically who was in control. I always knew at the end of the day which one of us had no financial ties to the facility and who could walk out and who would be left holding the equipment, leases/obligations.

There Is Always a Side Story

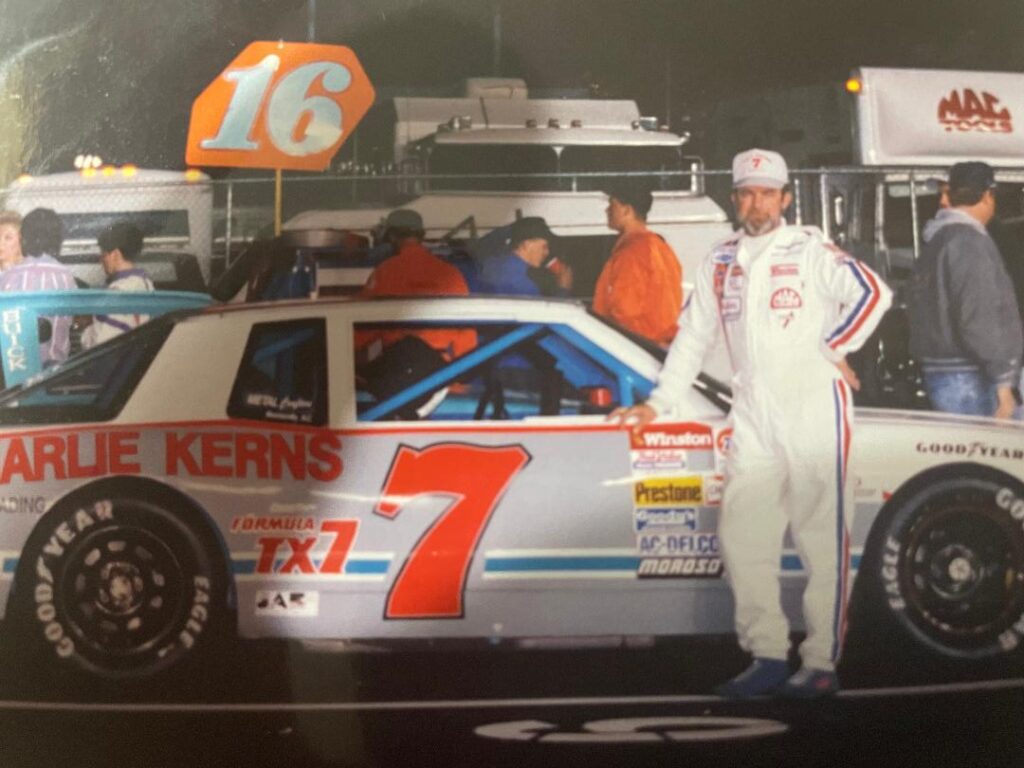

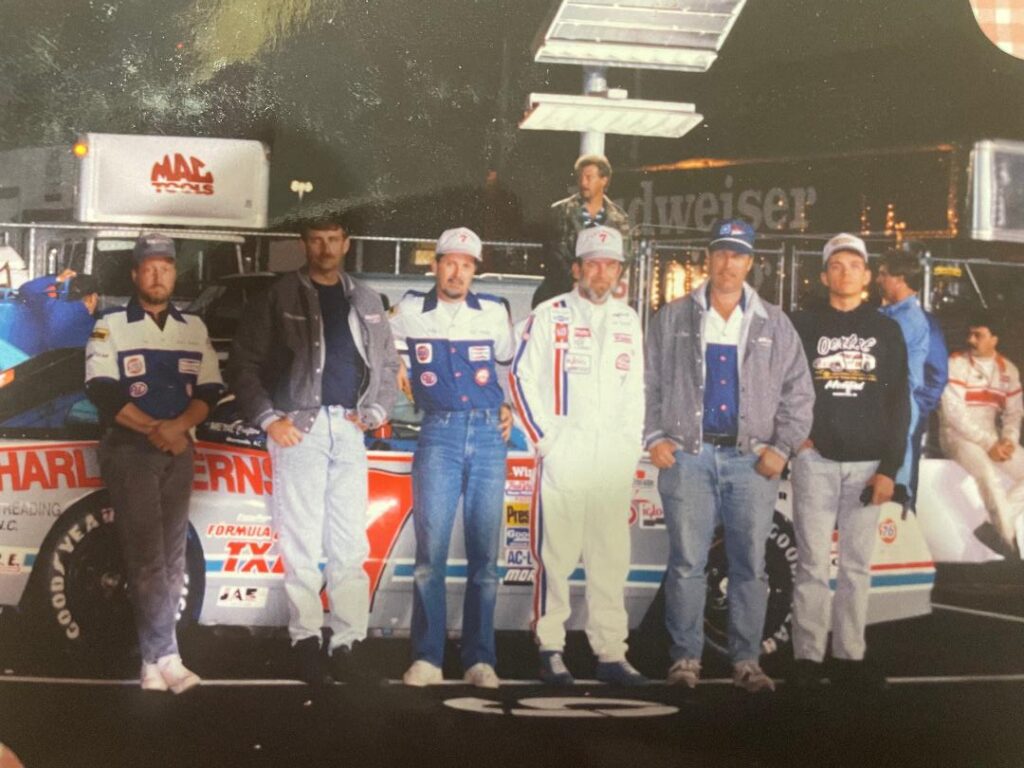

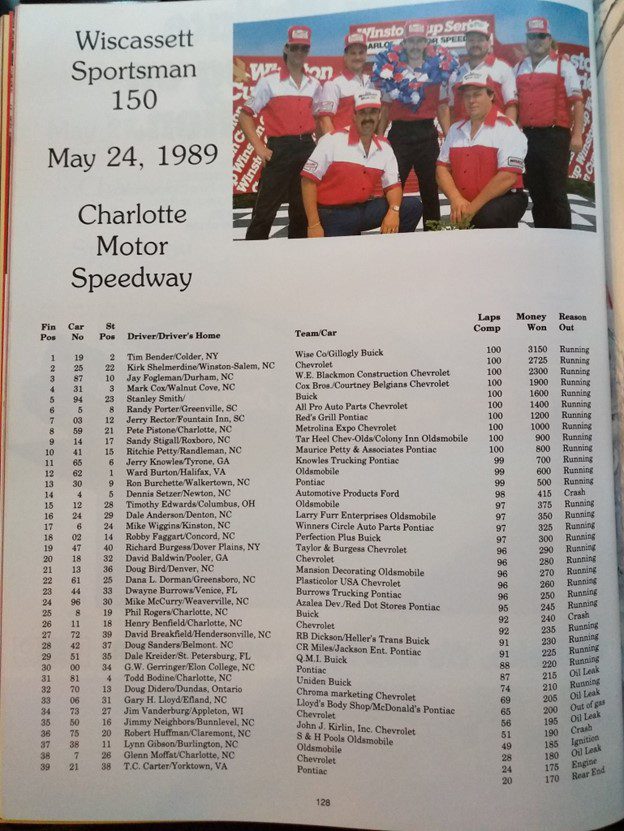

Doug was a duck out of water in the sportsman car, but a more than qualified racer, his theory of racing was simple hp, tires and downforce rule. Super modifieds had more than 2x the hp of a good sportsman car, 3x more tire footprint, 4x the downforce. The best sportsman racers were familiar with NASCAR stockcars, Saturday night LMSC drivers drove cars that were the same weight, wheelbase, tread width, same horsepower, another big deal was they were familiar with inspection process and inspectors. Doug’s sponsor deal was two races, the first race in May and one in October. Testing was a chore, Doug was used to being the fastest, the race car feel was so removed from super modifieds, in his mind it had to be the car. The car was stable at best, I told him ride, follow cars with similar speeds until his thermoset was fast as the car, then we would free the car up, by the afternoon he was in the top 15 consistently. First race he qualified 13th, a new product from Butler Built, a oil tank with a built in Oberg started leaking on lap 69. Doug chased Todd Bodine and Ward Burton in the top 15 until the tank issue. The second race for Doug included an intense test session, we were able to give him 50hp more. In the May race he started to relate tire grip, tight/push, being free not loose, how easy breaking the car loose with steering was and aero effects. Trying to explain to a dude that races on 16 in wide tires with 800 hp what finessing a sportsman car is about is like speaking German and thinking in redneck. It finally dawned on Doug that there is a sweet spot where tire adhesion, parasitic drag, downforce, and a phenomenon that allows the driver to set on top of the world at 154 mph. As we chased the combination Doug got faster and faster. Robert Hamke warned me earlier in the day not to crash him or he would be worthless. His suggestion rang through my head as Doug took the top speed on the practice list, Doug and Todd Bodine were in some kind of north of the Mason Dixon measuring contest. Doug asked for more, Carl Smith raised the trackbar one turn, I set the toe at -.125 inch, to the top speed he went, second lap Doug hit the dreaded Charlotte bump in 4 and into the wall he backed bounced off and into pit wall. Things define you on the way you handle the situation, I needed to sell this car to continue the adventure. On the way to the shop, I picked up a front steer clip from Hutch, we had a rear clip in stock for a quick-change car. By midnight we had her stripped and on the surface plate. By daylight both clips were welded on, Carl installed our body jigs, went through our bracket list, we prefabricated all the brackets welded them on then we painted our chassis, then took an 8-hour break. By Saturday mid-morning our team had the new suspension installed front/ rear back to race specifications and the body was under construction. By midnight we rolled the pig into the paint booth. Our original plan was to paint first than do the chassis dance, Carl suggested putting her in primer then the chassis alignment/ scale/ chassis dance based on the idea that after painting it took eight hours to dry. By noon Sunday the ole girl was ready to race. We rolled her in the paint booth by midnight we had 2 colors and a urethane clear topcoat, we had to be in inspection line shortly after noon, Monday, Fed Ex delivered the deck-els as Doug would say at 10am. The repair defined our business, Doug was fast off the truck, qualified 9th ran in the top 10 until our mystery oil tank issue flared up, we lost 2 laps. As we licked our wounds, we all knew we kicked its butt, a dude walked up and said I heard this car is for sale, I told him everything is for sale, he said I will have you a cashier’s check in your hand by Tuesday, another racer spoke up I want that car I can transfer the money by Friday. I told them both the first come with $25000 owns it. Tom Sherrill speaks up, “will you take a check?” I told him most definitely, Tom was one of us, crafty businessman I thought he was fueling the fire. In about two minutes as we were loading up, he handed me a $25,000 check. My business plan didn’t go past Monday without selling the car. Tom fixed that. The bunch from Arizona showed up Friday to buy the car, and left a down payment for a new $35000 Sportsman car just like the Raylene 70 car we sold to Tom. The dude from Florida that was going to have a check Tuesday ordered a second $35000 new sportsman car so at the end of the day I sold a used car and 2 new identical cars. Business Is Good.